At McDonald Brothers Construction (MBC), we are always looking for new ways of doing things. Since officially entering the construction industry in 1988, we have been constantly evolving and developing innovative ways to integrate sustainable constructability into our projects. Recently, we completed an affordable housing complex for Ottawa Community Housing (OCH) that houses senior residents, as well as the Carlington Community Health Centre. Located at 900 Merivale Road, the structure was completed in February 2019 and was one of the first Passive House structures built in Ottawa at the time of completion.

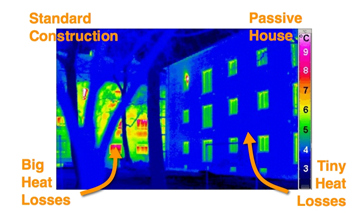

The concept of the Passive House design revolves around the idea of reusing heat in buildings. Essentially, the intent of the design is to construct a building that will not require heavy-duty heating and air conditioning appliances, and instead, primarily rely on its thick walls built using Insulated Concrete Forms (ICF) and highly rated insulation to keep tenants warm in the winters and cool in the summers. The driving force behind this is to minimize and phase out the excessive use of fossil fuels.

However, one of the prominent challenges with the Passive House design has to do with the building envelope. This design is extremely reliant on a highly insulated building and tight envelope; there can be no air leakage whatsoever. The air system also needs to extract as much thermal energy from the exhausted air to ensure its energy goals are met while maintaining a comfortable environment. Major emphasis on the building’s air barrier and air tightness was paramount on this project requiring significant quality control measures as it relates to intersecting air barrier details of assemblies to eliminate air leakage.

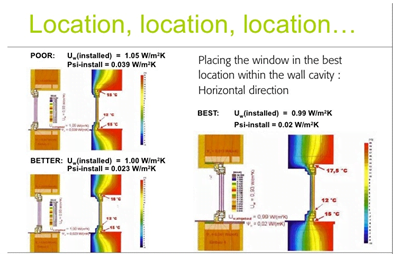

In addition to the building envelope, another major contributor to the success of the Passive House Design are the windows. Passive House structures must use thermal windows, in combination with a tight building envelope, to ensure they achieve the required energy efficiency. As a result, all windows on this project were thermal triple pane. Our colleagues at the Sustainable Architecture and Building (SAB) Magazine were kind enough to feature an article on our project in their Spring/Summer 2020 issue with input from our colleagues at CSV Architects who designed the superstructure. The article points out that, “operable windows are not needed for fresh air as the balanced ventilation system is designed with a capacity for two persons per suite but is run at 0.36 ACH, or 30 m3/h/occupant” (Page 41).

The feature also notes that the building only requires 132 KWhr/’m2/year which totals a reduction of 49% in energy savings. In addition, the water consumption from municipal sources is only 39,384 litres/occupant/year which is a total of a 40% reduction in water consumption.

However, the focus of this project was not only to decrease consumption statistics. Our teams worked collectively to incorporate a number of innovative construction practices that not only assisted in the decrease of energy consumption, but also enhanced the experience of the tenants who call this building home. As the article notes on page 41, the building was constructed in accordance with the WELL Building certification which promotes health and wellness amongst tenants through the incorporation of nature in the design.

The West side of the structure has substantial yard space for leisure, as well as open views from inside, which ultimately allows for the penetration of natural light into the building. This is also the case in many of the common areas of the building such as “public corridors, stairwells and common laundry rooms all feature large windows to provide natural sunlight and a connection to the exterior throughout the facility” (Page 41). As well, parking was limited to 64 spaces (which was the minimum number to comply with bylaws) and was crucial in the maximizing of green space for tranquility; this also required the total number of asphalt to be reduced. The inclusion of additional trees further assisted to the vitality of the new building. The structure also has a rooftop garden for tenants.

Additionally, the building has “exposed wood accents used throughout the structure, including two mass timber canopies and vestibules at the main entrance” (Page 41). The design team also mandated that all building material for this project was highly recycled and the wood had to be FSC certified. Water conservation also played a role in obtaining Passive House and WELL Certification as the fixtures include pressure-assisted flush toilets and low-flow shower heads.